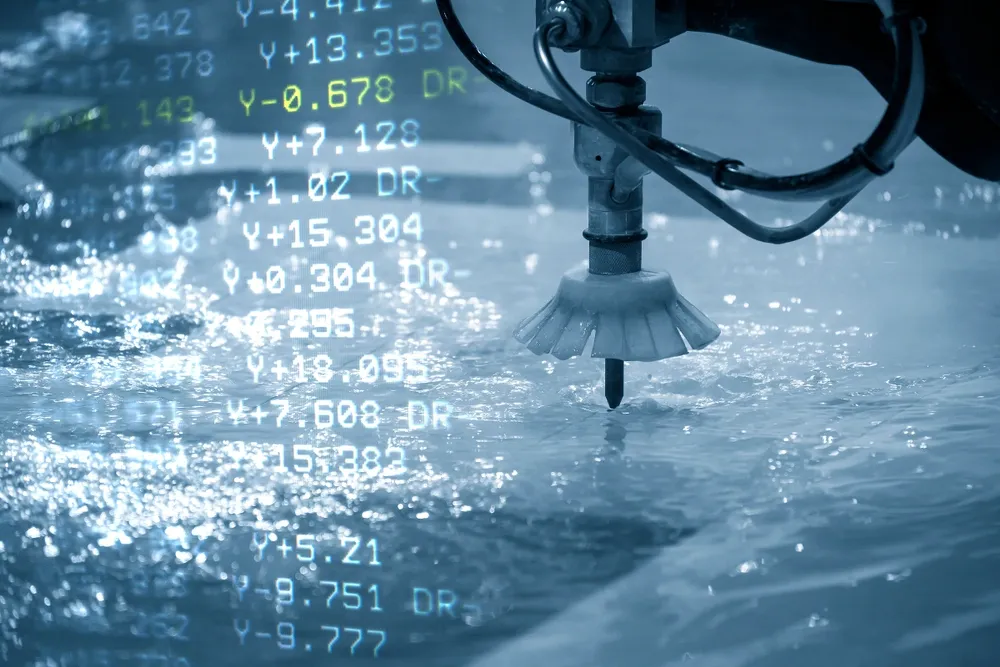

At Active Solutions, a leading provider of precision CNC mill machining services in Chandler, East Valley, our commitment to excellence extends beyond traditional machining methods. With our state-of-the-art 5-axis waterjet cutting technology in Arizona, we offer a versatile solution for cutting a wide range of materials with precision and efficiency. In this blog post, we’ll explore how waterjet cutting at Active Solutions optimizes the cutting process for maximum efficiency and precision across various industries, focusing on materials such as aluminum, brass, bronze, copper, and iron.

Aluminum: Precision in Aerospace and Automotive

Aluminum’s lightweight nature and exceptional strength-to-weight ratio make it a preferred material in aerospace, automotive, and other industries. At Active Solutions, our waterjet cutting technology enables precise cutting of aluminum sheets, plates, and extrusions for applications ranging from aircraft components to automotive body panels. With our advanced machinery and experienced staff, we ensure that aluminum parts are cut with unparalleled precision and accuracy, meeting the demanding needs of our clients in Chandler and beyond.

Brass: Craftsmanship and Aesthetics

Brass’s durability, machinability, and aesthetic appeal make it a popular choice for decorative and functional applications. From architectural accents to musical instruments, brass parts require precision cutting to achieve intricate designs and patterns. At Active Solutions, our waterjet cutting technology allows for the precise cutting of brass sheets and profiles, ensuring that every component meets the highest standards of quality and craftsmanship. With our attention to detail and commitment to excellence, we deliver brass parts that exceed our clients’ expectations.

Bronze: Strength and Durability

Bronze, a timeless material known for its strength and durability, finds its place in marine, architectural, and industrial applications. At Active Solutions, our waterjet cutting technology enables precise cutting of bronze sheets and bars for use in marine components, sculptures, and industrial machinery. With our advanced machinery and skilled staff, we ensure that bronze parts are cut with precision and accuracy, meeting the stringent requirements of our clients across industries.

Copper: Conductivity and Versatility

Copper’s high electrical and thermal conductivity, combined with its ductility and malleability, make it essential for electrical, plumbing, and heat transfer applications. At Active Solutions, our waterjet cutting technology allows for the precise cutting of copper sheets, rods, and tubes, ensuring that every component meets our clients’ exact specifications. Whether cutting electrical connectors or architectural accents, we deliver copper parts with unmatched precision and reliability.

Iron: Power and Utility

Iron, a fundamental material in construction, machinery, and infrastructure, requires precision cutting for optimal performance. At Active Solutions, our waterjet cutting technology enables precise cutting of iron plates, bars, and profiles for use in structural components, automotive parts, and industrial machinery. With our advanced machinery and experienced staff, we ensure that iron parts are cut with precision and accuracy, meeting the diverse needs of our clients in Chandler and beyond.

Optimizing Efficiency and Precision with Waterjet Cutting at Active Solutions

Waterjet cutting technology offers numerous advantages for cutting a wide range of materials with precision and accuracy. At Active Solutions, our 5-axis waterjet cutting technology in Arizona minimizes heat-affected zones, reduces material waste, and allows for intricate designs and tight tolerances to be achieved. Whether cutting aluminum for aircraft components or iron for industrial machinery, our waterjet cutting services deliver unmatched versatility and precision, ensuring that parts are manufactured to the highest standards of quality and reliability.